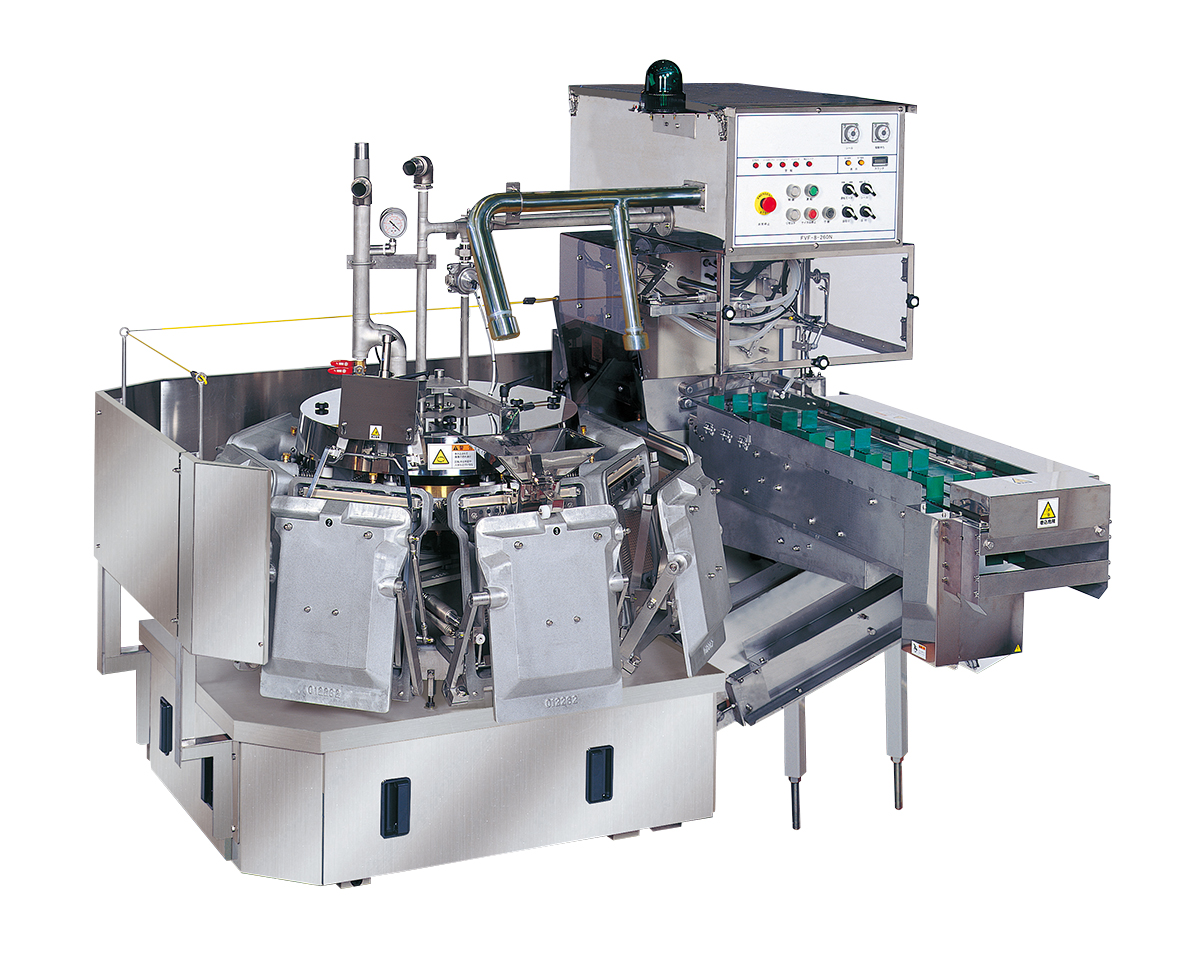

FVF Series Vacuum packaging machine

FVF-8-260N

*The discharge conveyor shown in the photogram is an option.

Main Features

- Empty bags from polyethylene bags to laminated bags can be supplied stably by providing the horizontal slide prevention guides in addition to the conventional conveyor system.

- Suction cups are adopted to hold bags in the vacuum chamber, making troublesome adjustments accompanying changes in bag width unnecessary.

- The motion of a machine becomes more smooth by controlling an inverter system, and designing the cam by a computer, and capacity is increased compared with the conventional machine.

- The maintenance becomes easy by opening and closing a vacuum chamber with one touch of a button while the sealing wire and a Teflon tape are changing, and the inside of vacuum chamber is washing. For the quality of the material, the corrosion-resistant aluminum alloy is also adopted.

- The opening/closing mechanism of the vacuum chamber is designed to absorb impact shocks, thereby resulting in smooth quiet operation.

- The space between a frame and a vacuum chamber becomes larger than before, and the entire frame is covered with a stainless steel. As a result, cleaning and washing properties are improved.

- The automatic weighing machine, feeding device can be interlocked.

Main Specifications

| Capacity (Bag/min.) | 15-22 |

|---|---|

| Usable bags/Width x Length (mm) | 200-250×280-380 |

*Capacity varies with product nature and vacuum pump size.