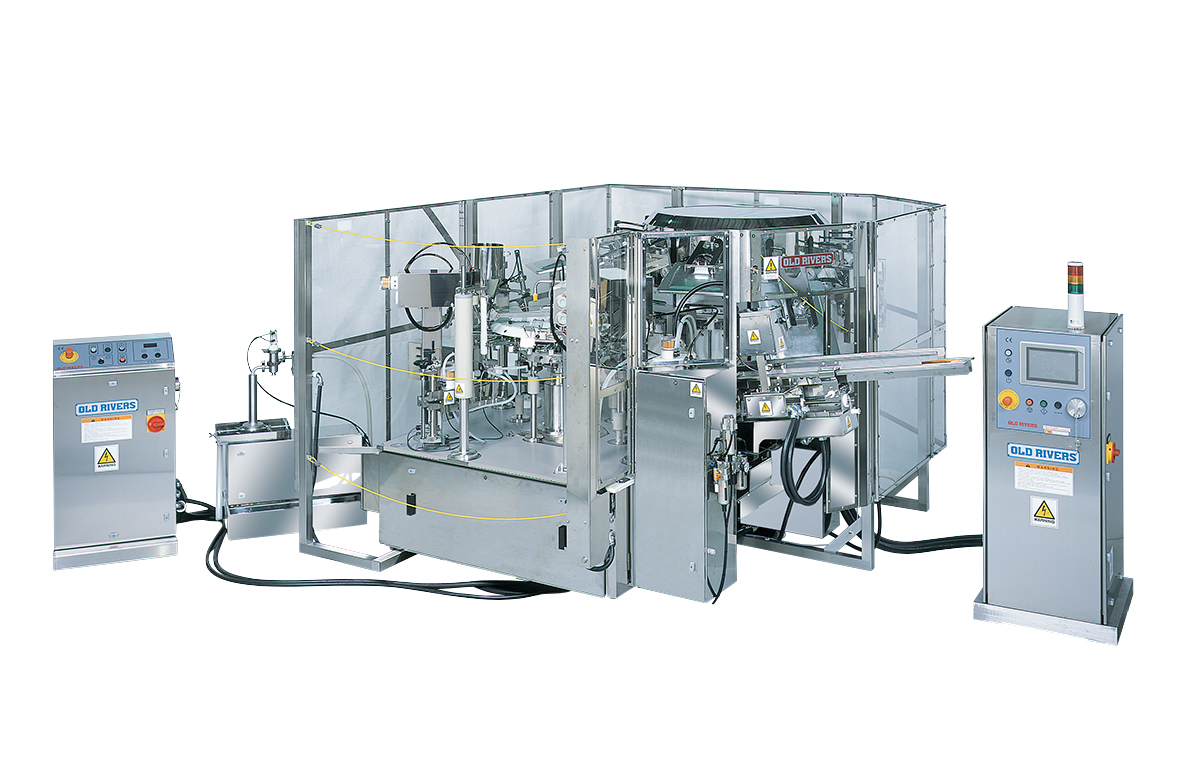

FVV Series Vacuum packaging machine

FVV-10×12-160G

The photograph shows the model of FVV-10×12-160GE of Europe specification.

Main Features

- The width of grippers on filling carousel is adjusted by a switch. The width of grippers inside of vacuum chamber does not need to be adjusted usually.

- Special shape bags such as standing bags, bags with zippers, etc. can be handled by mounting a special bag magazine (option).

- Gas can be filled up to atmospheric pressure owing to a sub-chamber system.

- The stable high replacement ratio can be acquired by putting a gas nozzle in a bag directly.

- The filling carousel moves intermittently so that products will be supplied easily, and the vacuum carousel turns continuously. The motion becomes smooth, and durability and a high speed packaging are improved.

- Since the bag recycling mechanism is provided as standard, there is no loss of empty bag.

- The external main parts are made of stainless steel and resin. The inside of the vacuum chamber can be washed with water.

- The inside of transparent vacuum chamber can be checked. (One transparent chamber as standard)

- The machine can be connected with the auto weighing machine and the feeding device.

- An inverter system can adjust a running speed with a dial.

- Various timing, degree of vacuum, seal time, etc. can be changed with one touch of a button on a screen since the touch-panel is provided.

- The central lubrication system is equipped (some parts of components are lubricated from the outside of machine.)

- The vacuum packaging can also be possible.

Main Specifications

| Capacity (Bag/min.) | 10-35 |

|---|---|

| Usable bags /Width x Length (mm) |

100-160×150-250 |

*Capacity varies with product nature, gas filling amount and vacuum pump size.